How healthy are your production automation systems?

Or how fit is it for the current production demand.

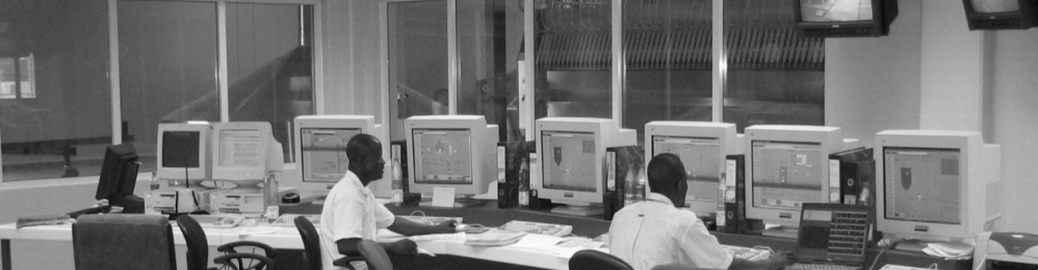

Production automation systems can have a wide variety of tasks. Simply from showing the field status of instruments to preventing operators from making mistakes, supervising processes, keeping inventories, making production schedules according runs and recipes.

Each automation system has a certain lifecycle and they tend to get shorter because of the availability of the used hardware, know-how of maintenance staff, but also the demand for the degree of automation.

Following items could be done during a health check. Of course also certain parts can be done, or focus on a special part.

- Inventory on as-is situation all hard- and software

Focus on one department, or all.

Guided self-assessment or fully assisted - Interview production, technical and management staff on how the process control system is working and assisting production.

- Spare parts availability in-house and at suppliers or original manufacturer

- Know-how and tools of technical staff for back-ups and restoring.

Identify knowledge gaps and demands from improvement - Skill of production staff to work with the systems

- Network connections to office and internet

- Protection of PC’s on the production floor

- Identify and prioritize risks for production stops caused by automation systems and know-how of operators and technical staff.

- Make a plan for restoring basic conditions